Home

Home Product

Product Laboratory Automation > Dairy Products Automated Testing Workstation > Raw Milk Impurity Detection Workstation

Laboratory Automation > Dairy Products Automated Testing Workstation > Raw Milk Impurity Detection Workstation

Return to List

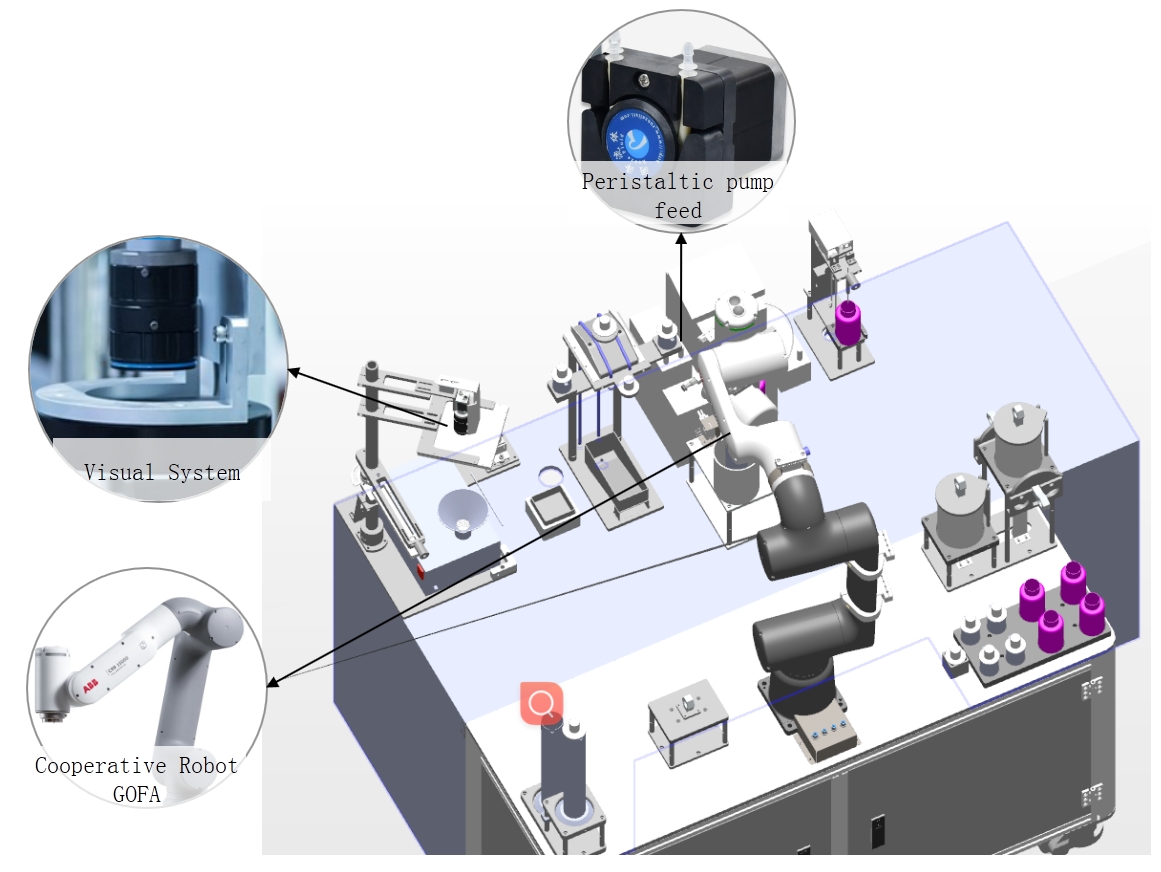

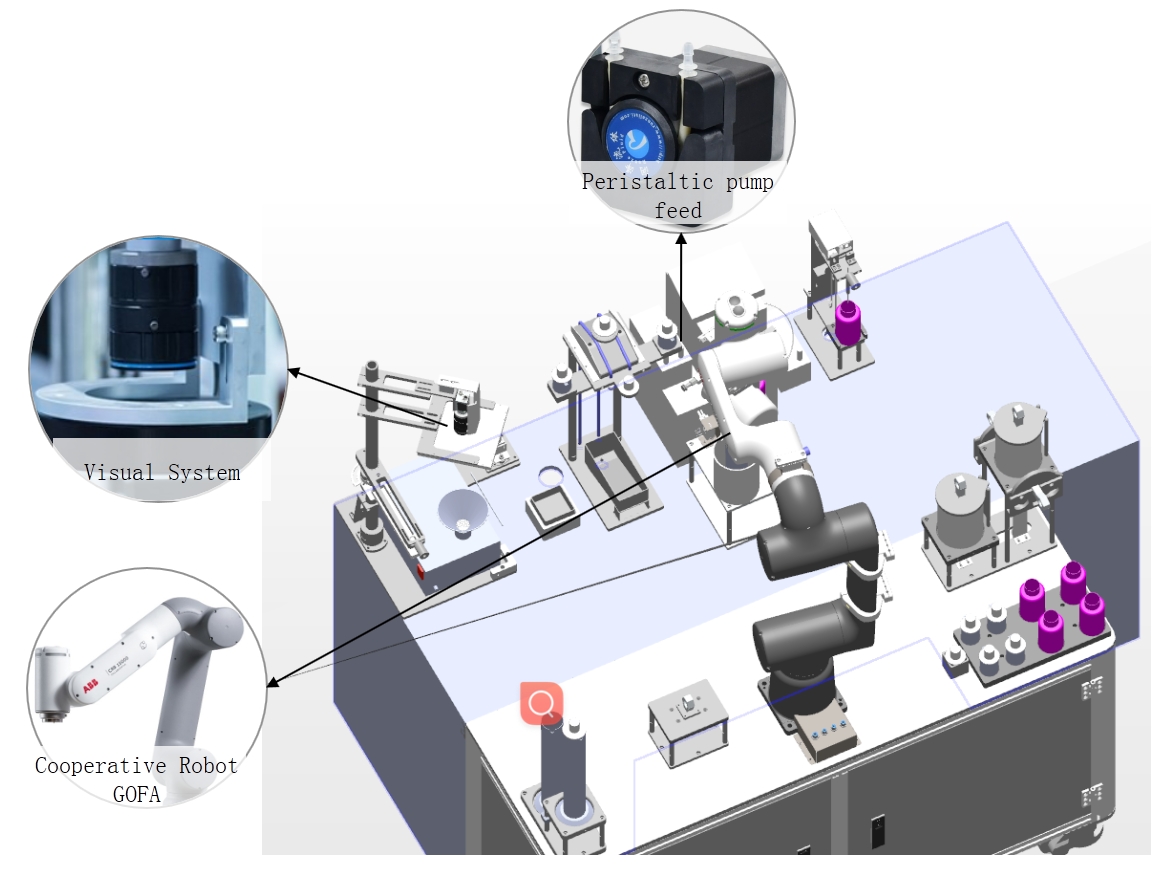

Raw Milk Impurity Detection Workstation

Return to List

Raw Milk Impurity Detection Workstation

Features

*Alita software control

-Alita software controls the experimental process, the process parameters can be edited, and the sequence can be reorganized.

-The robot communicates with Alita and performs detection actions based on the obtained task information, transferring samples and vessels back and forth at different detection stations.

-Liquid dispensing system: No bubbles generated, accurate to 0.1ml, with an accuracy of 0.5%

-Visual system: AI algorithm that automatically determines the purity level based on the area and quantity of residues. And communicate the results with Alita.

Application Fields

Fast Quality Check

Dairy Laboratory

Dairy Production Line

Product Service

On-site Technical Guidance

Efficient After-Sales Repair

Software Updates and Maintenance

About

Our Story Our Video PartnersCompany

News Video Contact OrderProducts

Robot Industrial Automation Agricultural AutomationGet digital marketing updates in your mailbox

Address

Address